Craft tire innovation excellence with the right integration and simulation strategy on the 3DEXPERIENCE® platform.

Industrial Equipment

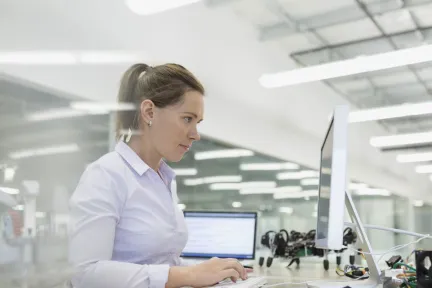

Digitalize manufacturing to deliver made-to-order innovation.

The growing trends of the 4th Industrial Revolution - automation, IoT, artificial intelligence, big data analysis, networked communications, machine learning and cloud computing – mark a significant change in the way we work and how we engage with our customers.

These emerging technologies are providing advanced and disruptive Industrial Equipment solutions that support the creation, production and delivery of sophisticated and efficient machinery, equipment and components.

Reimagining the Sustainable

World of Industrial Equipment

Explore the efficiency and interconnectedness of

this dynamic industry all in one place.

This experience only works in portrait mode.

Turn your device upright to switch to portrait mode.

Reimagining the Sustainable

World of Industrial Equipment

Click and drag the globe to explore

Click to see inside

Specialized Manufacturing Machinery

From Design To Manufacturing

Simplify Collaboration for Seamless Continuity

Specialized manufacturing machinery companies must foster collaboration across global operations to achieve enterprise agility. A unified platform integrates systems, suppliers and customers, providing a single source of information. This enhances decision-making, accelerates innovation and enables swift responses to market shifts, driving efficiency, resilience and competitiveness in a constantly evolving industrial landscape.

Specialized Manufacturing Machinery

Production Line Development

This content is hosted by a third party. By showing the external content you accept the terms and conditions of www.youtube.com.

Your choice will be saved in a cookie managed by Dassault Systèmes.

Optimize Manufacturing With Flexible Production Line

The shift from mass production to flexible manufacturing challenges specialized manufacturing machinery companies. They must leverage the 3DEXPERIENCE platform to seamlessly connect design, simulation and validation of flexible production lines. By using virtual twins, manufacturers can resolve issues before physical implementation, reducing lead times, enhancing agility and enabling rapid adaptation to evolving customer demands in a dynamic industry.

Specialized Manufacturing Machinery

Virtual Commissioning

Speed Up Commissioning With Virtual Twins

Specialized manufacturing machinery companies face pressure to reduce commissioning times and costs. Traditional methods lead to delays and errors. Virtual commissioning simulates production lines in a virtual environment, allowing engineers to test control logic and workflows. This results in faster time-to-market, minimized downtime, cost savings, greater efficiency and business agility.

Specialized Manufacturing Machinery

Field Service

Improve Field Operations With Real-Time Efficiency

After-sales services contribute from 30% to 60% of revenue for specialized manufacturing machinery OEMs. The demand for customized equipment encourages manufacturers to adopt outcome-based service models that maximize uptime and performance. Real-time equipment visibility helps predict failures, while a unified data analysis platform enhances efficiency, reliability and customer satisfaction in these markets.

Specialized Manufacturing Machinery

Marketing and Sales Experience

Transform Sales With Interactive Experiences

As demand for product personalization and customization rises, manufacturers face challenges in delivering tailored solutions efficiently. Traditional quoting processes often lead to longer sales cycles. Virtual twins transform this experience by allowing customers to visualize and customize equipment in real time, improving engagement and accuracy in quotations to drive faster sales and better customer satisfaction.

Heavy Mobile Machinery

Model-Based Systems Engineering (MBSE)

Simplify Complex Systems With MBSE

Model-based systems engineering (MBSE) in the heavy mobile machinery industry helps manage product complexity and deliver mission-critical solutions. Dassault Systèmes’ solutions connect requirements, design, simulation and validation in a unified environment. It streamlines workflows, reduces costs, ensures compliance and accelerates innovation.

Heavy Mobile Machinery

Engineering

Design and Manufacture Integrated Heavy Machinery

The industry faces global competition, multi-site operations, tight timelines, cost pressures and strict requirements for fuel efficiency and emissions compliance. Addressing these challenges requires a unified digital approach with integrated modeling, simulation and manufacturing tools in a seamlessly connected environment.

Heavy Mobile Machinery

Manufacturing

Ready To Make: Agile Manufacturing Anywhere

Mounting obstacles in the heavy mobile machinery industry have threatened productivity and efficiency. Rapid technological innovation and evolving regulations further add complexity, demanding a flexible and competitive production system that adapts quickly to market needs while achieving manufacturing efficiency.

Heavy Mobile Machinery

After-Sales Service

Keep Them Running: After-Sales Excellence

Heavy mobile machinery manufacturers are confronted with after-sales and service-related challenges including minimizing downtime, managing maintenance schedules and meeting customer expectations on reliability and performance. Virtual twins and data-driven insights can help optimize service operations, reduce costs and enhance customer satisfaction.

Tire Manufacturers

Sustainability-Driven Manufacturing

Greener Solutions for Tire Manufacturing

Tire waste is a serious environmental challenge. The mobility industry is pushed to lower emissions with sustainable tires to support the Paris Agreement. Adopting sustainable engineering allows tire makers to reduce environmental impact throughout the tire lifecycle by monitoring carbon footprint and cost in real time while ensuring regulatory compliance.

Tire Manufacturers

Tire Material Science Innovation

Advancing Tire Material Science

Material science is a key driver in tire innovation that transforms tire quality and safety. Tire manufacturers are utilizing advanced modeling and simulation tools to develop and test more durable materials to improve performance. With virtual testing and data-driven insights, manufacturers can accelerate development time and meet sustainability KPIs.

Tire Manufacturers

Tire Modeling and Simulation

Revolutionize Tire Vehicle Simulation

The tire industry is shaped by the demand for sustainability and stricter regulations. To adapt, manufacturers are embracing innovative business models and using predictive simulations to cut development and testing time by up to 25%, giving them a competitive edge in meeting targets.

Tire Manufacturers

Tire Engineering

Supercharge Tire Engineering With Innovation

Tire makers face key challenges such as supply chain disruptions, automation shifts and strict environmental regulations. However, with data-driven advanced simulation and virtual twin technology, they can revolutionize tire production through the SmarTyre industry solution. From optimizing performance to meeting sustainability goals, it enhances collaboration and streamlines the entire lifecycle.

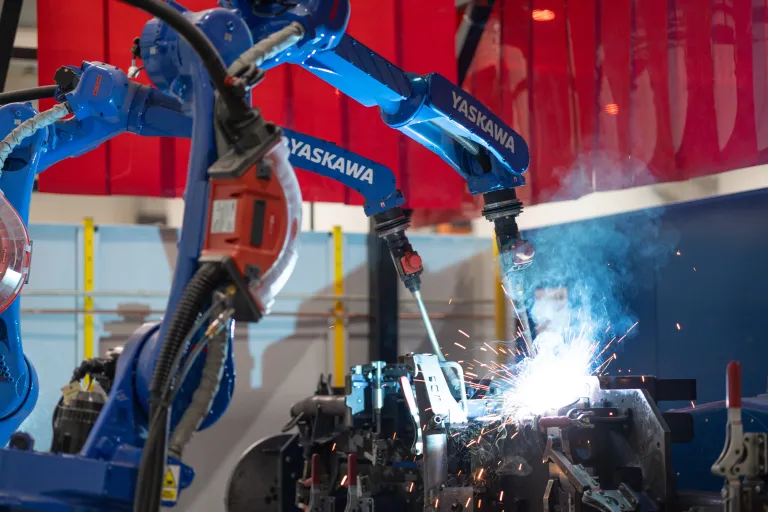

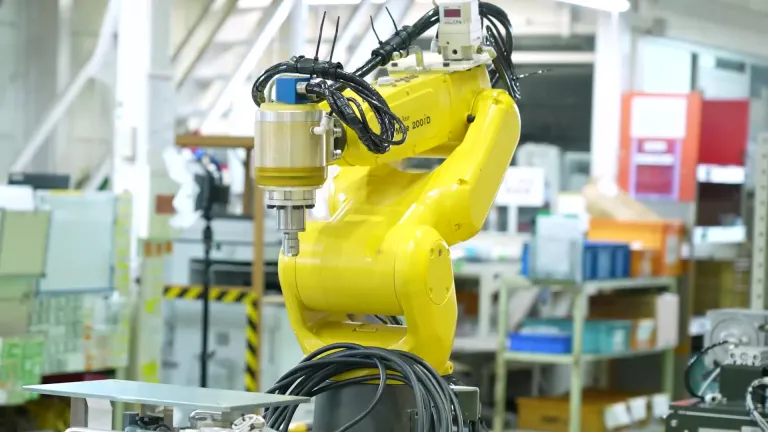

Industrial Robots

Connected Design Environment

Strengthen Collaboration With Digital Continuity

Designing innovative industrial robots requires technical expertise and creative problem-solving. Robotic engineers must design adaptable machines that prioritize safety and cost-efficiency while performing complex tasks to help manufacturers remain competitive through advanced technologies and agile design approaches. Integrating CAD data with the 3DEXPERIENCE platform enhances collaboration and streamlines workflows for faster product development.

Industrial Robots

Robot Programming and Simulation

Boost Innovation With Connected Robot Simulation

Virtual twins enable industrial robot manufacturers to integrate innovations into production lines virtually, minimizing risks and costs. By virtual simulating and testing robotic systems, manufacturers can address trends, overcome challenges and respond faster to customer demands. This approach boosts efficiency, reduces development time and costs for optimal performance. It also supports sustainability by minimizing waste and optimizing energy usage.

Industrial Robots

Flexible Production Lines

Optimize Processes for Flexible Manufacturing

Digital continuity enables industrial robot companies to define and optimize production lines virtually before physical implementation. This approach minimizes risks and costs while accelerating the time-to-market by streamlining processes and enhancing collaboration. By utilizing virtual twins, companies can achieve greater flexibility, adapt to evolving customer demands and promote more sustainable manufacturing practices.

Industrial Robots

Service Process Engineering

Achieve Service Excellence With Robot-as-a-Service

The Robot-as-a-Service (RaaS) model allows a subscription-based revenue for manufacturers while providing flexible and cost-effective automation solutions. They can retain their robot ownership while providing maintenance services that ensure optimal performance and minimize downtime through data collection and monitoring. RaaS secures consistent revenue, enhances service quality and makes automation more accessible to a wider customer base.

Serving the needs of all stakeholders across the Industrial Equipment value chain

Single-function machines are being replaced by all-in-one equipment that covers the entire production process. To win more deals, manufacturers need to propose smarter and more flexible machines.

Driving Sustainable Innovation in Robotics, Machine Tools, and 3D Printing for Manufacturing Leadership.

New technologies have transformed how power and fluidic equipment is designed by providing increased flexibility, accuracy, analytics and customization capabilities.

Empowering Fabricated Metal & Plastic Products Manufacturers to Drive Sustainable Innovation and Maximize Efficiency, Quality, and Profitability reaching Manufacturing Excellence.

The construction, mining and agricultural sectors need robust and efficient heavy mobile equipment that are tailored to the demands of the activity and comply with national regulations.

Rising fuel and raw material costs, fierce competition, and stringent safety and environmental regulations are just some of the challenges facing today’s tire manufacturers

When it comes to building equipment, end user comfort and safety are essential. That’s why OEMs pay particular attention to design, compliance and equipment efficiency.

Addressing the business challenges of the Industrial Equipment Industry

Emerging technologies are providing Industrial Equipment solutions that greatly revolutionize how manufacturers and suppliers of any size go-to-market.

Adopt a smart and flexible business environment to develop and deliver personalized products more rapidly than ever before

Accelerate machine versatility and performance from anywhere

Ensure your business has the agility to meet the highly competitive pressure of customer demand.

Keep operations running smoothly and expand after-sales revenue potential by including servicing needs at the beginning of the product development process

Manage business risks to adapt and respond to any internal or external opportunity, demand, disruption, or threat

Unlock new sources of value: building sustainable and resilient industrial equipment in the circular economy.

In the Spotlight

Craft tire innovation excellence with the right integration and simulation strategy on the 3DEXPERIENCE® platform.

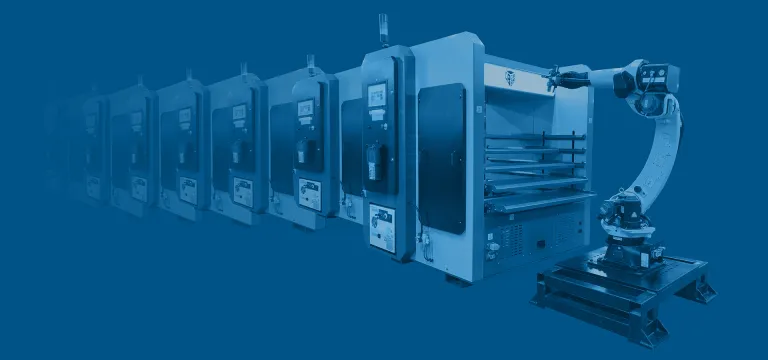

Develop, integrate, manage and maintain flexible production lines with autonomous mobile robots.

Virtual twins and advanced analytics drive performance optimization, operational efficiency, and superior customer service.

In a four-part series, experts reveal how the virtual twin delivers electrolyzers of the future to meet the demands of green hydrogen production.

Model-Based Systems Engineering (MBSE) revolutionizes heavy mobile machinery and equipment development, enhancing collaboration, efficiency, and innovation

Leverage the 3DEXPERIENCE platform for greater field operations efficiency, after-sales services and success in the industrial equipment scene.

Explore our recent customer stories

The Finnish company uses the Digital Equipment Continuity industry solution to design and manufacture steel structures and service platforms while improving data management and collaboration.

Polish Stelweld is shaping the future of metal fabrication with its latest welding techniques and adopted the 3DEXPERIENCE platform to refine its production processes. With the Digital Equipment Continuity industry solution experience, the company can create a seamless workflow and has the ability to simulate and virtually test product designs, helping them to meet customer demands faster while maintaining high quality standards.

To foster greater synergy between its two subsidiaries, Korean construction machinery company HD Hyundai XiteSolution needed to create a common global product development management system to integrate their design, product lifecycle and bill of materials management capabilities.

Shanghai-based robotic line builder CNBM Triumph Robotics adopted the 3DEXPERIENCE platform's Digital Equipment Continuity industry solution experience to streamline and standardize its way of working. With virtual commissioning, customers now experience the production lines through virtual twins, which support them with diagnostics, equipment upgrades and training.

Italian company CAREL specializes in electronic control solutions for air conditioning, refrigeration and heating systems and uses the 3DEXPERIENCE platform on the cloud for its development processes. By adopting the Digital Equipment Continuity industry solution experience, CAREL is able to connect all disciplines and systems, which shortens configuration and production time, reduces errors and offers more customization options.

Japanese robotic assembly line builder Yutaka Electronics chose Dassault Systèmes’ 3DEXPERIENCE platform on the cloud and its industry solution experience Digital Equipment Continuity to ensure that the systems it has designed for its customers are operating correctly and efficiently before it begins physical commissioning.

Korean heavy mobile equipment manufacturer Hyundai Everdigm serves the construction and civil engineering sectors with its fire trucks, concrete pump cars, hydraulic drills and more. The company migrated from its legacy PLM system to Dassault Systèmes’ 3DEXPERIENCE platform, using industry solution Digital Equipment Continuity to transform its product development, optimize its manufacturing operations and achieve a continuous data flow across the entire product lifecycle.

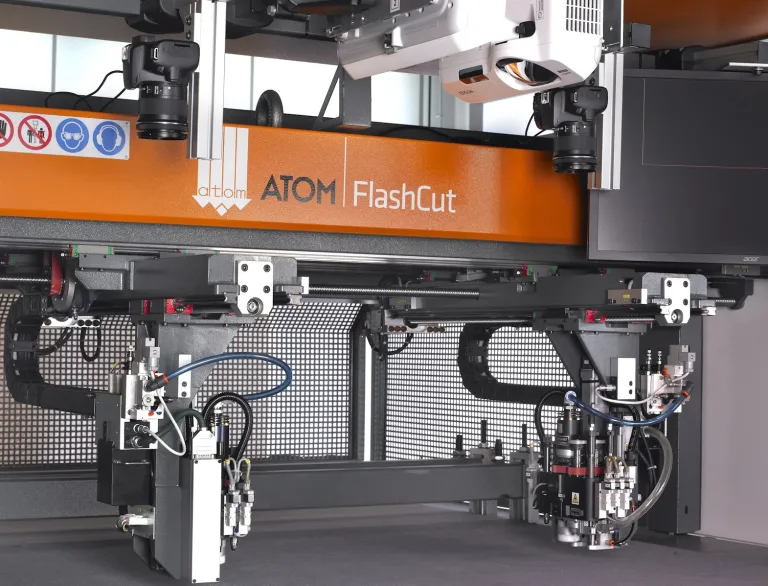

Italian cutting machine manufacturer ATOM CUTTING is a leading global provider of innovative cutting systems for a range of industries from fashion to aerospace and uses the 3DEXPERIENCE platform on the cloud for its product development processes. With the Digital Equipment Continuity industry solution experience, ATOM can centralize all product development data and bring together different disciplines within a single environment.

Struggling to manage the large and complex assembly data for its robotic automation systems, Tezmaksan Robot Technologies relies on Dassault Systèmes’ solution for its powerful design and data management capabilities. The Digital Equipment Continuity industry solution experience provides a centralized environment through which the engineers can work concurrently in real time, reducing duplicate data and improving efficiency.

Trends in the Industrial Equipment Industry

Article

Leveraging MBSE for Next-Gen Heavy Mobile Equipment and MachineryModel-Based Systems Engineering (MBSE) revolutionizes heavy mobile machinery and equipment development, enhancing collaboration, efficiency, and innovation

Article

Data-Driven Approach to After-sales ServicesVirtual twins and advanced analytics drive performance optimization, operational efficiency, and superior customer service.

Article

Empower Your Company With Total Quality ManagementEmbrace an intelligent end-to-end approach to quality with the 3DEXPERIENCE Platform